Strapping Materials

B.F. Pack strapping solutions is a full-service manufacturer and supplier of strapping materials, equipment, and systems for a multitude of applications and industries.

Durability, Performance, and Security are the three pillars of our strapping division. We make sure all our materials are used for safety, on the one hand for our employees, customers, and on the other hand, load unit security while traveling. Our great performances are reflected in our product innovations, our services, and our lasting partnership with our customers. Specializing in the production, distribution, and development of premium quality strapping made from PET and PP, so we ensure safe and ideally suited materials for your specific conditions of use.

What Do You Need To Know About Strapping?

They're basically packaging accessories that are used to secure goods like boxes and pallets for the use of transportation. These strapping materials are available in various widths and thicknesses and are all made of different materials like textile, steel, or plastic. We at B.F Pack offer you plastic transport protection made out of polypropylene (PP) and Polyester (PET)

What Is Strapping Used For?

- Compressing - The use of strapping for your good, so the straps tear strength and pressure keeps your product in its shape and supports safe transport.

- Securing - With the help of strapping, security for the transported goods is ensured.

- Building - One of the most common purposes, to bundle loose goods that cannot be packed in boxes.

- Closing - The use of strapping is to prevent the opening of the box during transportation.

STEEL STRAPPING BAND

The oldest and commonly used banding materials are designed for extreme tasks that need a heavy or extremely heavy-duty strap. The use of steel strapping is optimal for packaging industrial equipment, heavy construction materials, etc. Steel strapping owns its benefits like large loads, sharp edges, high break strength, UV resistance, great durability. Few applications that are used around are steel coils, baling wires, bricks & pavers, bundles of metal, and roll end-binding.

Read More

PET / POLYESTER STRAPPING BAND

The most commonly used polymer strapping material with its durability and strength being made the most used material to replace the use of steel strapping. The help of a high level of elongation and recovery makes the strapping for packaging loads susceptible to shifting. The help provided by the elongation makes it easier to minimize the effect of a sudden shift. The tools involved in Polyester Strapping Band are H23 Manual Plastic Strap Tensioner Tool, P403 Manual Combination Plastic Strap Tool, P328 Battery Powered Plastic Strap Tool, P358 Pneumatic Plastic Strap Tool.

Read More

PP / POLYPROPYLENE STRAPPING BAND

An economical strapping material as compared to the other materials used. The designing for a polypropylene strapping band is designed for light to medium duty palletizing, utilizing, and bundling. Few of the features of a polypropylene strapping band is it has a high level of elongation, low strength, little recovery.

Read More

COMPOSITE / POLYCORD STRAPPING BAND

A cord strap that is also known as synthetic steel, is a high-quality composite corded strapping product. It used polyester fiber coated with clear polypropylene. Amongst the other strapping solutions, composite corded strapping is the newest technology for cargo securing. Composite strapping is used for heavy loads and for carried loads under difficult conditions.

Read More

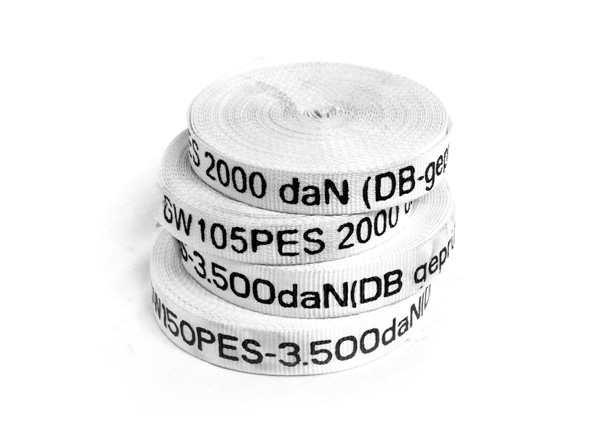

WOVEN LASHING BELT

The use of a lashing belt is to secure the transportation of cargo by road, by railway, or by the sea in a container. It is used mainly for the transport of heavy industrial products and for the stabilization of cargo inside the container. A woven lashing belt is used for loads carried by a crane or an elevator, ensuring the loads in the vehicle are stabilized against the dynamic movements.

Read More